Invention-Factory

Invention Factory is an intensive summer program for Cooper Union undergraduate engineering students. In 2016, we presented the prototype of our design of a universal screwsriver nammed Push and Twist. Our design won second place of that year's invention factory and recived a $3000 cash reward.

Back to Protfolio

Push & Twist Screwdriver

The Problem

Conventional screwdrivers are used only for screws of one type and one size, thus usually require the user to carry more than one screwdriver for mechanical jobs. Even though most screwdrivers come with interchangeable tips aim to increase its usage, we found that it could still be a hassle to change tips to fit different screw shapes. Thus, our invention aims to eliminate the inconveniences of carrying multiple screwdrivers and the process of changing different screwdriver tips.

There are just too many types of screw heads

Our Invention

Our invention is a universal screwdriver that can turn all common screws. It is in the form of a keychain attachment. It is with you any time and it fits any shape. it is perfect to use for an in a pinch situation such as changing the battery of your child’s toy.

How it works

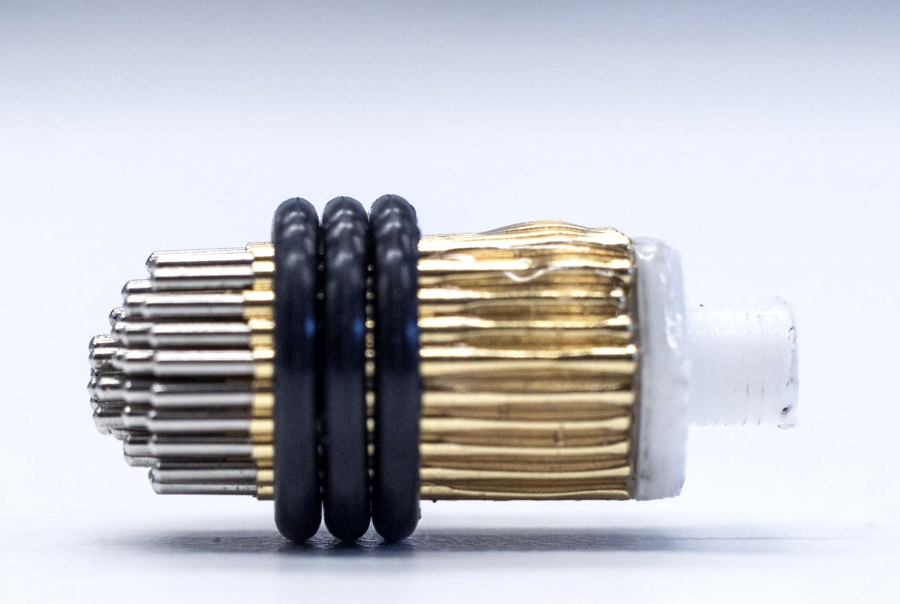

The uniqueness of the screwdriver lies in its head, which consists of many spring-loaded thin rods. When you push the device onto a screw head, those thin rods will conform to the shape of the cavity on the screw head. All of the rods are attached to a stage-liked base by means of weld or glued. And a protective sleeve surrounds this bundle of rods.

Current Prototype

This concept of thin rods morphed to the shape of the screw cavity is proven feasible through many iterations of prototypes. Our most recent prototype uses a bundle of retractable probe pins that are available on the market at a relatively low price. This prototype successfully turns screws with Phillips head, slotted, Allen, Torx, etc.

Here is a drawing for the probe pin we use

Design Feature 1

Since we were designing for a range of sizes, if the screwdriver cross-section is larger than the screw head, some rods may stick out and scratch the surface of the workpiece when it gets to the end. Thus we made our product to have a “V shape” design, having the outside rods shorter than the inside ones.

Design Feature 2

The product has a detachable head and replaceable so that it can be inserted into a screwdriver shaft when more torque is needed. Moreover, if the rods get mangled after a long time of usage, a new head can be simply replaced.

A video demo of the detachable head

Testing on Material and Strength

In our current prototype, the rods are made of brass, which has a relatively low yield strength. We desired our final product to be made of carbon steel or hardened stainless steel, to make the product stronger.

We have tested with thin rods made from carbon steel. The diameter of the rods is 0.8 mm.

We also did a tip-loading test for the 0.8 mm diameter carbon steel rods. On average, the yielding point with an effective length of 1/8’’ is 3 lb. We have more than 50 rods bonded together in our prototype, and on average, for a size 10 screw Philips head, more than 10 rods get inserted in the cavity and dissipated the load together.

2 Sizes

Our product comes in two sizes. The regular one has rods with a smaller diameter than the large one. We are designed for commonly used household screws. Which are size 6 to size ¼ in. and our regular one is perfect for all. It is convenient and portable and can be used in an -in-a-pinch situation.

The large size has a more focused size range, from size 10 to size ¼, but it can exert more torque and has a longer lifetime than the regular one. It is suitable for situations such as occasional furniture assembly.

Patent Drawing and Intellectual Property

Here are some of our patent drawing showing the detail of our design

Mingyang Lee and Yueyue Li are the co-inventors of this invention, and the intellectual property is protected under the provisional patent application (U.S.62358445).